Plug & play containers

GAZ SYSTEMES offers the possibility of tailoring the installation of medical fluid production plants in containers.

The containers are delivered “Plug & Play”, that is to say all the connections inside the container have already been done, whether they are electric, pneumatic or linked to ventilation.

GAZ SYSTEMES offers many options, from the color of the container, its insulation, its floor covering to the installation of additional doors or windows.

1. Types of containers

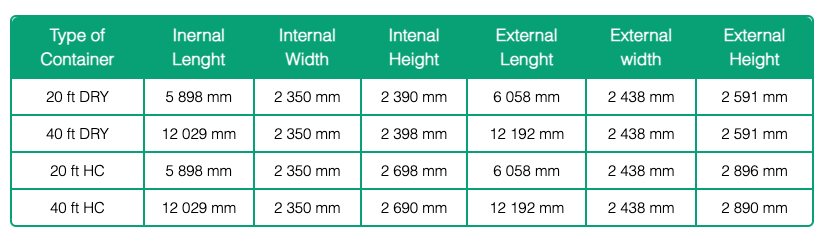

Size of shipping containers

The size of the container is mainly dictated by technical constraints related to the footprint of the equipment and the respect of a minimum distance between the devices in order to carry out maintenance operations.

All containers can be shipped by sea as standard. The main types of containers used are as follows:

- 20 feet DRY container

- 40 feet DRY container

- 20 feet HC container (High-Cube)

- 40 feet HC container (High-cube)

High-Cube containers have the advantage of having an interior height that is thirty centimeters higher than our standard DRY containers. This 30 cm gain allows all of the GAZ SYSTEMES oxygen production plants to be integrated in containers.

Other containers and portable cabines

It is possible to ship these installations in containers or portable cabins that are not approved for maritime transport, provided that the shipment to the customer is made by road or in goods that fall outside the by sea category.

The 6.8 and 10 foot containers and Algeco-type portable cabins are suitable for the smallest power stations.

2. Containers Insulation

The insulation of production containers is almost inevitable given the heat released by the compressors (although a large part of this heat is extracted from the container) but also local weather conditions, temperature and exposure to the sun.

If the container is positioned under a shelter, in a temperate climate, insulation will not be compulsory although strongly advised. GAZ SYTEMES teams will advise you on the best technical solution to adopt while respecting your budget.

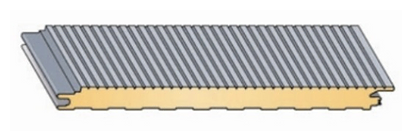

The standard insulation offered by GAZ SYSTEMES is composed of sandwich panels of up to 120mm thick. The sandwich panels are composed of two sheets of 0.2mm thick galvanized steel. In between each layer of steel is a layer of polyurethane-based insulation.

The panels are installed on all the internal walls of the container: walls, ceiling and doors.

Opposite sectional view of a sandwich panel. The outer part is galvanized and the inner part is white lacquered in standard configuration

3. Connection of production equipment

Pneumatic Connection

The pneumatic connection between the different components of an oxygen or medical fluid production plant is essential. In fact, a pneumatic connection must be optimized to limit pressure losses, prevent the transmission of vibrations, avoid the formation of condensation in the pipes due to temperature gradients or even ensure safety against electrical accidents.

When GAZ SYSTEMES installs containers, all of these elements are taken into account:

- All connections are made of high quality stainless steel, degreased for oxygen contact. The installation in the container is made up of stainless steel, whether it is meant to be used for compressed air, vacuum, scavenging of anesthesia gases or nitrous oxide.

- The pipes are supported by high quality isophonic collars, and the pipes are all electrically connected to earth.

- The piping is optimized to avoid low points and when they are unavoidable, they are fitted with a condensate trap.

4. Containers Ventilation

Very important care is taken in the design and installation of an adequate ventilation system. Indeed for several reasons it is essential to ventilate the container properly:

- The composition of the air in the container must remain similar to that of the outside to provide sufficient oxygen to the generator.

- Air temperature must be within the lower capacity limits of each equipment

To allow these conditions to be fulfilled, the following elements are systematically implemented in GAZ SYSTEMES containers :

Channeling of gaseous waste outside the container

The production of oxygen by PSA technology produces nitrogen in the air as waste. It is essential to channel this nitrogen release outside the container and in directions opposite to the fresh air inlets.

GAZ SYSTEMES provides for each generator with nitrogen extraction niches intended to release nitrogen directly outside the container in the lower part.

This evacuation of gaseous waste also applies in the case where the container is equipped with a vacuum central as well as a central evacuation of anesthesia gases.

Air Extraction systems

Compressor hot air extraction ducts

Lubricated scroll compressors produce hot air due to the necessary cooling of the oil at the outlet of the compression block. This hot air must be released outside the container to maintain the correct temperature in the container. This extraction can be carried out in two ways, either via a natural extraction sheath or an electrical extraction sheath.

This extraction also helps to renew the air in the container.

Electrical air Extractors

In addition to the hot air extraction ducts of the compressors, GAZ SYSTEMES systematically installs wall air extractors allowing efficient artificial air circulation.

The capacity of the extractors depends on the configuration of the production plants, the minimum being the installation of an extractor with a minimum capacity of 2000 m3/h.

Ventilation gratings

The extraction of air requires in return a renewal of fresh air in the container. This renewal is ensured via ventilation grids located on the walls and the floor of the container.

The surface occupied by these grids is generally equal to 0.15m2 per kW of installed power.